Building a Sustainable Future: Importance of Reusing and Recycling Construction and Demolition Waste through Value Additions

Dr. R.M.L.D Rathnayake - Senior Lecturer, University of Peradeniya

Introduction

Construction and Demolition Waste (C&DW) refers to all non-hazardous solid wastes resulting from construction, maintenance, renovation, and demolition works in construction industry. Waste generation in construction activities can arise from many sources, such as construction work, reconstruction work, demolition activities, land-clearing exercise, various natural disasters and etc. Some of the major components in C&DW such as polythene, plastic, glass, concrete, asphalt and heavy metal contained paints can cause detrimental impacts on any ecosystem and human health.

C&DW is one of the major contributors to the solid waste generated globally (Poon & Chan, 2007). For instance, in Australia, C&DW comprises 15% of overall waste (Mcdonald & Smithers, 1998), while in Malaysia, the figure rises to 41% (Eusuf et al., 2012). In India, the construction industry contributes 23% of total soil waste generation (Poon & Chan, 2007). However, much of this waste ends up in uncontrolled landfills worldwide causing significant environmental and health issues.

Improper disposal of C&DW leads to pollution of land, water, and air, with materials like concrete, plastic, glass and asphalt releasing contaminants that harm ecosystems and biodiversity. The extensive use of natural resources like sand and timber in construction activities exacerbates resource depletion. Moreover, studies indicate that, construction consumes 40% of the raw stone, gravel, and sand used globally each year and 25% of the raw timber (Cheng et al., 2006).

In the quest for a sustainable society, the C&DW management is pivotal to minimize environmental effects. On the other hand, a transformative approach to reusing and recycling the C&DW can significantly help for a sustainable future. Recently, there has been an investigation into the utilization of construction and demolition waste (C&DW) to develop alternative practices aimed at adding value to the waste material. This involves explaining the reasoning behind selecting particular methods for enhancing its value. For instance, studies have explored the possibility of using clay bricks and concrete fines to treat wastewater contaminated with cadmium, lead, and chromium (Kumara et al., 2019a; 2019b; Bandara et al., 2020), highlighting the significance of reusing or recycling C&DW for various purposes through value addition.

Accordingly proper C&DW management strategies must be adapted to minimize environmental damage. In addition, over-generous material wastage within construction sector can negatively affect project profitability. Thus, it is paramount to reduce material wastage promoting reuse and recycle in order to poster environmental sustainability, preserving the economic viability of construction projects. This article focuses on C&DW generation, its characteristics and possible recycling and reusing attempts as one of the major pathways of sustainable C&DW management.

C&DW generation and their characteristics in Sri Lanka.

In Sri Lanka, the construction industry has been contributing the GDP by about 7%, however, the amount of C&DW generated in the country has not been accounted clearly. A recent study by Gunawardhana (2020) reported that total C&DW generation is 5.4 ± 4.4% of material used in construction. The relative compositions of each material types in C&DW waste shown in Table 1. As revealed in this literature it is evident that the C&DW is a resource which is comprised of numerous recyclable and reusable elements.

Table 1: C&DW compositions in Sri Lanka

Reuse and recycling of C&DW and its important

The reuse and recycle of C&DW waste help to achieve considerable environmental benefits, which enables conserving natural finite resources with a trivial impact related to raw material extraction. Additionally, it is possible to reduce carbon emissions influentially through recycling materials such as concrete, contributing to combat against global warming. Promoting reuse and recycle in the construction industry not only makes progress towards sustainable environment but also creates job opportunities. Waste management in the construction industry, through such circular economic approaches of materials, reduces raw material cost while recycling helps to create markets which boost economic growth and employment opportunities. Such initiatives do not contradict the principles of the circular economy, which supports resource efficiency, waste reduction, and development of a sustainable and self-regenerative system

Innovation to recycling of C&DW (Case studies)

Two case studies from University of Peradeniya, Sri Lanka report below unfolds how the engineering and innovation can drive a sustainable construction industry though recycling C&DW.

Case study 1: Development of Asphalt for road pavement with waste aggregates and polythene

(Janath, 2023, This study was supervised by the author of this article)

Recycling the discarded aggregate remains important for sustainable practices within the construction industry. One possible direction for improvement is the use of waste plastic to improve the mechanical characteristics of these aggregates while addressing the dilemma of sorting out its waste. On the other hand, plastic coating can change the surface condition of low-grade aggregates which are now considered to be ideal for construction purposes.

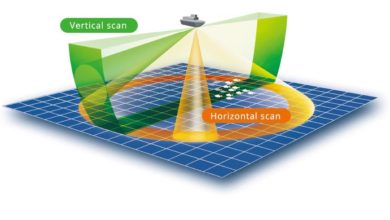

Figure 1: Experimental procedure in production and testing of asphalt using waste aggregate and plastic in case study 1 (Manchanayake, 2020, (Janath, 2023, This study was supervised by the author of this article)

In innovative research which was conducted in the Environmental Engineering Laboratory, University of Peradeniya, Sri Lanka waste aggregate was pretreated by applying plastic coat on the aggregate surface (Manchanayake, 2020). The Engineering properties such as mechanical strength and binding potential of plastic-coated waste aggregate (PCA) were tested to investigate the improvement of those properties. Interestingly all the mechanical properties of waste aggregates were improved beyond the permissible levels. Thereafter, in order to investigate the performances of asphalt prepared with above PCA standard laboratory tests such as Marshall stability test, Stripping value test and Bitumen extraction test were carried out. Remarkably, all the tested samples satisfied the recommended standards indicating that this PCA is a potential recycling option for aggregate and polythene in C&DW as road paving asphalt production.

Case study 2: Development of pours concrete using recycled waste aggregates (RCA).

(Janath, 2023, This study was supervised by the author of this article)

The growing infrastructure development has imposed a tremendous challenge for urban drainage systems, as their infiltration has been hindered leading adverse operational conditions, like urban flooding. The sustainable drainage systems enhance the reduction of urban runoff by increasing the infiltration of storm water. The use of porous concrete has been recognized as an efficient solution for managing storm water runoff allowing more infiltration and enhanced removal of storm water pollutants.

Figure 2: Experimental procedure in production and testing of asphalt using recycled coarse aggregate and plastic in case study 2.

As a solution of urban runoff and C&DW, the recycled coarse aggregate (RCA) was used to develop a porous concrete and key attributes such water absorption, specific gravity, compressive strength, and turbidity removal were investigated (Figure 2) (Janath. A, 2023). The results of the study revealed that RCA can be effectively used in production of porous concrete, as they show recommended mechanical properties (i.e., compressive strength) and other prominent properties such as workability and water infiltration rates. Interestingly, prepared porous concrete exhibits remarkable turbidity removal ability which added additional advantage to the porous concrete manufactured with RCA. Moreover, cost analysis of above porous concrete production suggests that the use of RCA rather than natural aggregate is economically viable in producing porous concrete. Therefore, the use of this RCA was recommended to substitute in the development of sustainable drainage systems, thus enabling practical implementation and fostering advancement in urban drainage management practices.

Summary

A sustainable management of C&DW is essential due to various reasons. Reuse and recycling of C&DW is one of the potentials was of achieving it. The recent case studies shed lights on the recycling potential of D&DW though research and innovations to promote sustainable practices lowering environmental damage. Through these innovations, the industry should be able to leverage increased efficiency, resource conservation, and a more resilient world while furthering the global initiative of mitigating pollutions and enforcing sustainable practices.

References

Bandara, A.B.P., Kumara, G.M.P., Matsuno, A. Kawamoto, K (2020) Examination of crushed laterite brick for removal of chromium and arsenic from wastewater. Inte. Jour. Geomate. 19(74), 22-30.

Cheng, E. W. L., Chiang, Y. H., & Tang, B. S. (2006). Exploring the economic impact of construction pollution by disaggregating the construction sector of the input-output table. Building and Environment, 41(12). https://doi.org/10.1016/j.buildenv.2005.06.020

Eusuf, M. A., Ibrahim, M., & Islam, R. (2012). The construction and demolition wastes in Klang Valley, Malaysia. Planning Malaysia, 10. https://doi.org/10.21837/pmjournal.v10.i3.103

Gunawardhana, W. A. P. C. P., Madushanka. R. M. L. , Dissanayake. P. B. R., Kawamoto. K., and Rathnayake. R. M. L. D. (2020). Construction and demolition waste generation and its management in Sri Lankan building construction projects. Environmental Monitoring and Management Conference, 91.

Janath. A. (2023). Sustainable Drainage System Modeling Support Decision Making – Recycled Concrete Aggregate used Porous Concrete [MSc]. University of Peradeniya.

Kumara, G.M.P., Kawamoto, K. (2019a) Applicability of crushed clay brick and municipal solid waste slag as low-cost adsorbents to refine high concentrate Cd (II) and Pb (II) contaminated wastewater. Inte. Jour. Geomate. 17(63): (2019), 133-142.

Kumara, G.M.P.; Kawamoto, K. (2019b) Steel Slag and Autoclaved Aerated Concrete Grains as Low-Cost Adsorbents to Remove Cd2+ and Pb2+ in Wastewater: Effects of Mixing Proportions of Grains andLiquid-to-Solid Ratio. Sustainability, 13, 10321. https://doi.org/ 10.3390/su131810321.

Manchanayake, M. A. M. O., Nirosani. K. P., Sumathipala. H. M. C. M., Fernando. M. H. Y. K., Dissanayake. P. B. R., Kawamoto. K., and Rathnayake. R. M. L. D. (2020). Recycling of low-quality waste aggregate with plastic coating for asphalt production. Environmental Monitoring and Management Conference, University of Peradeniya, Sri Lanka, 88.

Mcdonald, B., & Smithers, M. (1998). Implementing a waste management plan during the construction phase of a project: A case study. Construction Management and Economics, 16(1). https://doi.org/10.1080/014461998372600

Poon, C. S., & Chan, D. (2007). The use of recycled aggregate in concrete in Hong Kong. Resources, Conservation and Recycling, 50(3). https://doi.org/10.1016/j.resconrec.2006.06.005

Dr. R.M.L.D Rathnayake

Senior Lecturer

Environmental Engineering Laboratory, Department of Civil Engineering, Faculty of Engineering

University of Peradeniya